Hindustan Petroleum Corporation Limited (HPCL)

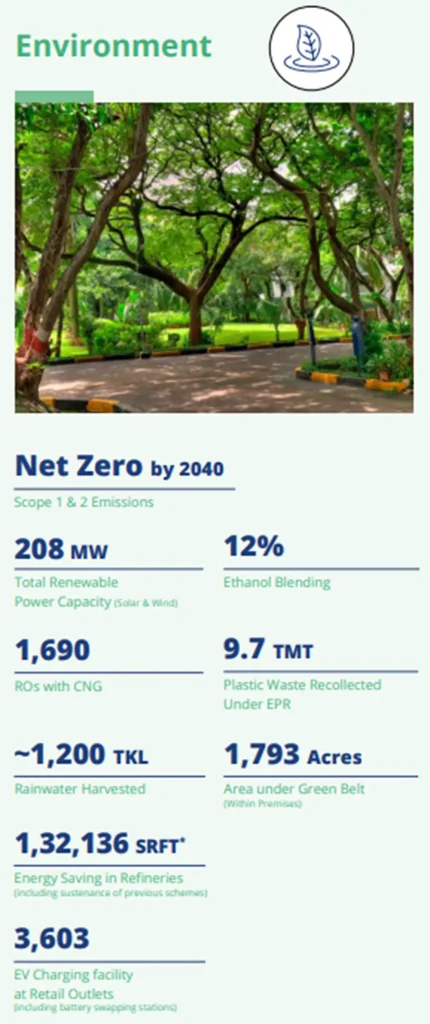

Hindustan Petroleum Corporation Limited (HPCL) is committed to advancing environmental sustainability through energy efficiency, carbon footprint reduction, water conservation, and waste management. The company aligns its environmental strategy with long-term sustainability goals to protect ecosystems and promote a healthier planet.

Key Initiatives

- Environmental Management: HPCL integrates the triple bottom line approach (financial, social, and environmental) to enhance sustainability. Its operations focus on energy efficiency, rainwater harvesting, reforestation, and biodiversity conservation.

- Best Practices Adoption: Advanced environmental management systems, hazardous waste disposal, effluent treatment, and air quality monitoring have been implemented at major locations. Technologies like VOC monitoring, leak detection and repair (LDAR), and vapour recovery systems (VRS) help minimize emissions.

- Climate Strategy: HPCL sets self-determined GHG reduction targets, benchmarking against industry peers. It explores decarbonization through fuel substitution, green hydrogen, renewable energy, energy efficiency, flare reduction, and carbon capture, utilization, and storage (CCUS).

- Sustainability Recognition: HPCL is India’s first oil & gas company to adopt the GreenCo Rating System, with 35 certified locations as of March 2024. It received the GreenCo Champion award from CII for implementing sustainability assessments.

- Governance & Employee Engagement: A Board-level CSR and Sustainability Committee oversees sustainability efforts. Employee incentives, awareness campaigns, and training on fuel-efficient driving are integral to climate action.

- Investments in R&D: HPCL invested ₹352.50 crore in R&D for biofuels and emission reduction and ₹10,829.94 crore in efficiency improvements, renewable energy, and infrastructure modernization.

- Mission LiFE Participation: Supporting India’s Mission LiFE, HPCL promotes climate-conscious behaviors through awareness drives, tree plantations, waste collection, and stakeholder engagement via social media and the Meri Life Portal.

HPCL’s sustainability-driven approach aims to achieve Net Zero by 2040, positioning the company as a leader in environmental stewardship in the energy sector.

Energy Management at HPCL

Hindustan Petroleum Corporation Limited (HPCL) prioritizes energy conservation to enhance efficiency, reduce emissions, and lower operating costs in refining and marketing operations. The company actively monitors energy consumption, implements advanced technologies, and adopts best practices to optimize energy use.

Key Highlights

- Energy Consumption & Intensity:

- Total energy consumption in FY24 was 6,33,75,126 GJ, a rise from 5,56,81,796 GJ in FY23 due to increased operations.

- Renewable energy accounted for 0.184% of total consumption.

- Energy intensity per refinery throughput improved from 2.92 GJ/MT (FY23) to 2.84 GJ/MT (FY24).

- External energy use for product transportation and employee commuting was 8.64 million GJ.

Energy Conservation Initiatives

- Refineries:

- Mumbai and Visakhapatnam refineries implemented 22 energy-saving projects, saving 1,32,136 SRFT/year.

- Specific energy consumption was 75.0 MBTU/BBL/NRGF (Mumbai) and 80.5 MBTU/BBL/NRGF (Visakhapatnam).

- Energy Saving Certificates (ESCerts): Mumbai Refinery earned 38,665 ESCerts under the Perform, Achieve, and Trade (PAT) scheme.

- Marketing Operations:

- Energy efficiency measures include real-time monitoring, high-efficiency equipment, power factor optimization, LED lighting, and periodic energy audits.

- Pipeline operations reduced Specific Energy Consumption significantly through optimization efforts.

- Certifications & Benchmarking:

- 116 locations are ISO 50001:2018 certified for energy management.

- HPCL ranked in the top 6th percentile globally in Solomon Global Benchmarking for cost-efficient energy management.

- Achieved 100% paperless asset management via Linear Asset Management (LAM) for enhanced sustainability.

HPCL actively monitors and discloses its Greenhouse Gas (GHG) emissions across Scope 1 (direct), Scope 2 (indirect from energy use), and Scope 3 (value chain emissions). In FY24, Scope 1 emissions reached 4.72 million tCO2e, Scope 2 emissions 1.06 million tCO2e, and Scope 3 emissions 137.37 million tCO2e, with key reductions achieved through energy-saving initiatives and renewable energy adoption.

The company implements various sustainability projects, including:

- Biofuels: 12% ethanol blending, second-generation ethanol biorefinery, compressed biogas plants.

- Natural Gas: Expansion of city gas distribution networks, LNG dispensing outlets.

- EV Infrastructure: 3,603 outlets with EV charging stations.

- Renewable Energy: Wind and solar power projects, a 100 MW solar project in Andhra Pradesh.

- Green Hydrogen: A 370 TPA green hydrogen plant at Visakh Refinery.

- Logistics Optimization: Pipeline transport expansion, reducing road transport emissions.

HPCL follows IPCC methodologies for emission calculations and has strengthened methane mitigation efforts with Leak Detection and Repair (LDAR) programs. Under CSR, it has installed solar streetlights and expanded LPG access under the Pradhan Mantri Ujjwala Yojana (PMUY). For air quality, HPCL employs technologies such as low-NOx burners, sulfur recovery units, and flue gas desulfurization to control NOx and SOx emissions. Continuous monitoring ensures compliance with environmental regulations.

Biodiversity Initiatives

Biodiversity, encompassing species and ecosystem variability, is crucial for ecological balance, human well-being, and climate resilience. HPCL integrates biodiversity conservation into its operations, ensuring green cover and habitat preservation at its locations.

Key Biodiversity Efforts:

- Green Belt & Habitat Protection: HPCL’s controlled areas support diverse flora and fauna, including herbal plants, fruit-bearing trees, and migratory birds. Regular maintenance sustains biodiversity.

- Project Planning & Compliance: Environmental considerations, including impact assessments (EIA), green buffers, and regulatory adherence, are integrated into site selection and operations.

- Environmental Initiatives: Under the “Panchatattvon Ka Maharatna” theme, HPCL promotes afforestation, rainwater harvesting, and biodiversity enhancement.

- Ecologically Sensitive Sites: Compliance with environmental clearance is ensured at sites within Coastal Regulation Zones (CRZ), such as Kandla Terminal and Chennai New Terminal.

- CSR & Conservation: HPCL supports Goa-based Coastal Impact for marine ecosystem restoration, including coral transplantation. Additionally, it has adopted three Red Pandas (Himalayan Zoological Park, Sikkim) and two Tigers (Sanjay Gandhi National Park, Mumbai) to support endangered species conservation.

Hindustan Petroleum Green R&D Centre (HPGRDC) is spearheading energy transition innovation through research, indigenization, and cost optimization. It supports refineries and marketing units by developing cutting-edge, sustainable technologies across refinery processes, petrochemicals, renewables, and battery storage.

HPGRDC operates from an IGBC Platinum-rated, state-of-the-art facility spanning 170 acres, housing 20 advanced laboratories dedicated to green solutions such as biofuels, hydrogen production, and carbon capture. In FY24, the Centre successfully developed over 36 new products, filed 104 patent applications, and holds a total of 547 patents worldwide.

Key R&D Focus Areas:

- Indigenization of refinery technologies and chemical additives

- Process intensification and novel separation techniques

- Renewable energy, biofuels, and battery storage

- Development of sustainable aviation fuel (SAF) and green hydrogen solutions

HPGRDC has established strategic partnerships with global and national organizations, including KBRL, Oil India, HRRL, Net Zero Technology Centre, Tata Projects, and the University of Birmingham. It has also commercialized key technologies such as Vapour Recovery Units, medical-grade oxygen production, and sustainable fuel processing.

Recognized with prestigious awards such as the CHT Innovation and FICCI awards, HPGRDC actively contributes to industry knowledge through technical forums and workshops. With increasing R&D investments, the Centre remains committed to pioneering low-carbon technologies in alignment with India’s Net Zero goals.

Specialized Research Areas:

- Process Chemicals & Lubricants: HPCL has developed advanced process chemicals for industrial applications, including demulsifiers, corrosion-resistant coatings, fuel additives, and cleaning solutions. Its lubricants and greases portfolio covers automotive, industrial, and marine-grade oils, with specialty products for defense and agriculture.

- Petrochemicals & Polymers: HPCL is advancing sustainability with bio-based antioxidants, 3D-printable polypropylene, biodegradable polymers, and recycled polymer solutions.

- Bioprocesses: Innovative biotechnology solutions include bioremediation of oily sludge, biomass-based ethanol production, and high-efficiency biogas generation.

- Nano & Battery Technology: Breakthroughs include nanocomposite-based coatings, sodium-ion batteries, and lithium-ion cylindrical cells, enhancing energy storage and corrosion resistance.

- Engine Technologies & Low-Carbon Solutions: HPCL has successfully tested alternative fuels, including methanol blends, additized gaseous fuels (H-CNG), and diesel-biodiesel-ethanol blends. Additionally, the company is pioneering the production of SAF and green diesel from used cooking oil to lower aviation emissions.

- Carbon Capture & Utilization: HPCL is developing technologies for CO₂-to-methanol and dimethyl carbonate conversion to mitigate refinery emissions. It is also exploring biomass pyrolysis and hydrothermal liquefaction for renewable fuel production.

Water Management at HPCL

Water is essential for HPCL’s operational and non-operational needs, including refinery processes, cooling, firefighting, and domestic consumption. Recognizing its critical role and the challenges posed by water scarcity, HPCL is committed to conservation, efficient usage, and sustainable water management practices.

The company continuously implements new technologies and methodologies to optimize water use, such as high-efficiency fixtures, waste reduction strategies, and water reuse and recycling systems. Water consumption is monitored using mechanical and electronic measurement techniques, and rainwater harvesting is actively pursued at operational sites, benefiting both HPCL and surrounding communities.

Effluent Treatment and Recycling

HPCL refineries and key marketing locations employ Effluent Treatment Plants (ETPs) and Sewage Treatment Plants (STPs) to recycle wastewater. Treated effluents meet Minimum National Standards (MINAS) and are repurposed for cooling towers, fire safety systems, and horticulture. Water discharge is closely monitored to ensure minimal environmental impact. During the reporting period, there were no significant water-related incidents affecting revenues or water bodies.

Water Risk Mitigation Approach

HPCL has developed a structured approach to minimize water-related risks, including:

- Identifying locations vulnerable to water stress

- Monitoring water usage and implementing corrective actions

- Promoting water reuse, recycling, and recharge initiatives

- Raising awareness and engaging stakeholders through training programs

Water Consumption and Withdrawal (FY24)

- Total Water Withdrawal: 9,15,47,112 KL

- Total Water Consumption: 1,72,87,404 KL

- Water Intensity: 0.77 KL/MT Refinery Throughput

Water Discharge (FY24)

- Total Water Discharged: 7,42,59,708 KL

- Seawater discharge: 7,42,16,285 KL

- Third-party discharge: 703 KL

- Other destinations: 42,720 KL

Water Management in Water-Stressed Areas

As of March 31, 2024, HPCL has identified 37 marketing locations in water-stressed regions based on India’s 2023 National Groundwater Resources Report. The company prioritizes water conservation at these sites, focusing on:

- Installation of water-efficient fixtures

- Reuse and recycling of water through ETPs and STPs

- Enhancing awareness through training and communication

Key Achievements in Water Conservation (FY24)

- 12,04,465 KL of water recycled at HPCL refineries

- ~12,00,000 KL of rainwater harvested through 497 rainwater harvesting structures

Through these initiatives, HPCL continues to strengthen its water stewardship efforts, ensuring responsible water management while supporting India’s sustainability goals.

Waste Management Initiatives

The organization implements efficient waste management practices by identifying, segregating, recycling, and disposing of waste per regulatory norms. Regular assessments are conducted to minimize waste generation and environmental impact.

Hazardous & Non-Hazardous Waste Management:

- Hazardous waste, including spent catalysts and oily sludge, is managed through authorized recyclers and Pollution Board-approved facilities.

- Bioremediation techniques are used for low-oily sludge.

- Non-hazardous waste, such as plastics and metal scrap, is either recycled or disposed of per government regulations.

Key Waste Management Initiatives:

- Plastics: Collection through Extended Producer Responsibility (EPR) and disposal via authorized recyclers.

- E-waste: Disposed of through registered recyclers as per E-waste (Management) Rules.

- Biomedical Waste: Processed through authorized agencies.

- Metallic Scrap: LPG cylinders, valves, and other metallic components are recycled through government-approved vendors.

- Organic Waste: Converted into compost using organic waste converters.

- Construction & Demolition Waste: Primarily disposed of via landfilling.

Innovative Circularity Measures:

- Bio-additives (HP-Bioremedia): Developed for enhanced bioremediation of hydrocarbon sludge.

- Recycled Plastic Tiles (Pilot Project): Using 100% recycled plastic waste to replace concrete paver blocks.

- Plastic Waste in Roads: Mixed with bitumen for road construction, reducing landfill waste.

Waste Disposal Data (FY24 Highlights):

- Total Waste Generated: 45,312.1 MT

- Recovered (Recycled/Reused): 9,707.5 MT

- Disposed (Incineration/Landfilling): 35,604.6 MT

The organization aligns its operations with sustainability goals by emphasizing green chemical alternatives and responsible waste management while continuously improving its processes.

Sustainability at HPCL’s Residential Complex

Established in 1954, HPCL’s Housing Complex (HC) has fostered community living while implementing various sustainability initiatives. Over the years, HPNE and HPNW complexes have introduced eco-friendly measures, including solar PV systems, LED streetlights, rainwater harvesting, drip irrigation, and waste management systems.

In 2023-24, new initiatives were launched:

- Aushadh Manav – A unique human-shaped horticultural project featuring 117 medicinal plant varieties.

- Reflexology Path – An 80-meter-long path designed to stimulate acupressure points.

- Sewage Treatment Plants – Two plants (30 KLD and 40 KLD) using advanced Japanese Johkasou and Aerated Wetland methods.

- Miyawaki Plantation – 2,000 plants grown with a 90% success rate.

These efforts have earned multiple accolades, including first prizes in horticultural exhibitions and garden competitions, as well as second place in ‘Best Overall Participation’ within the metropolitan region.

To know more, visit –