Steel Authority of India Limited (SAIL)

SAIL operates its plants and mines in strict compliance with environmental regulations governing emissions, waste management, and ecological conservation. The company prioritizes sustainability by integrating green practices into its operations, ensuring minimal environmental impact while maintaining ecological balance. As a responsible corporate entity, SAIL is committed to clean, sustainable growth by embedding ethical and transparent environmental policies into its business framework. Its Corporate Environmental Policy, available on its official website, extends beyond regulatory compliance, focusing on stakeholder engagement and environmental responsibility.

Decarbonization Roadmap

Phase I (2005-2023)

- 20% reduction in CO₂ emissions through energy-efficient technologies like BF-TRT, WHR, CDCP, & LED lighting.

- 22 million trees planted and eco-restoration projects launched.

Phase II (2023-2031)

- Increase crude steel production to 31.49 MT while reducing CO₂ emissions by ~12%.

- Expand renewable energy usage & adopt breakthrough green technologies.

Phase III (2031-2070)

- Full-scale integration of Industry 4.0 & AI-driven process optimization.

- Increased use of renewable energy & advanced carbon capture technologies.

- Innovations in low-carbon steelmaking & waste-to-energy solutions.

Environmental Performance (FY 2023-24)

Energy Consumption & Efficiency

- Total energy consumption: 614,166 TJ (up from 591,147 TJ in FY 2022-23).

- Renewable energy share: 266 TJ (up from 230 TJ).

- Non-renewable energy use: 613,900 TJ (up from 590,917 TJ).

- Energy intensity per revenue: 0.560 GJ/₹ (slightly improved from 0.570 GJ/₹).

- Designated Consumer (DC) status: All 5 Integrated Steel Plants identified under PAT Scheme (Performance, Achieve & Trade).

Water Management & Zero Liquid Discharge (ZLD)

- Total water withdrawal & consumption: 57.4 million KL (up from 55.3 million KL).

- Water intensity: 3.02 m³/tcs (reduced from 3.06 m³/tcs).

- Water discharged to surface water: 22.9 million KL (up from 22.3 million KL).

- ZLD initiatives:

- 123 million m³/year wastewater treated & recirculated.

- 2235 m³/hr effluent treatment capacity installed.

- Lagoon expansion at RSP (+3 lakh m³ capacity).

- Future SAIL units planned with ZLD concept.

Air Emissions & Greenhouse Gases (GHG)

- NOx emissions: 0.76 kg/tcs.

- SOx emissions: 1.10 kg/tcs.

- Particulate Matter (PM10): 0.58 kg/tcs (slight increase from 0.57 kg/tcs).

- Scope 1 emissions: 52.6 million tonnes CO₂ (up from 47.6 million tonnes).

- Scope 2 emissions: 2.44 million tonnes CO₂ (down from 3.02 million tonnes).

- GHG emission intensity per crude steel: 2.90 tonnes CO₂/tcs (up from 2.80 tonnes CO₂/tcs).

- Scope 3 emissions: 5.3 million tonnes CO₂ (reduced from 5.62 million tonnes).

Waste Management & Circular Economy

- Total waste generated: 14 million tonnes (up from 12.7 million tonnes).

- Waste intensity per revenue: 128 t/₹ (increased from 122 t/₹).

- Waste recovery & recycling:

- 3.14 million tonnes recycled.

- 8,673 tonnes reused.

- 11.2 million tonnes sold for recovery.

- Landfilling reduced to 2,358 tonnes (from 3,529 tonnes).

- Hazardous waste managed as per CPCB guidelines.

- 100% utilization of iron slag in cement industry.

- Steel slag used in blast furnaces & sinter-making to replace limestone.

- BOF slag used in agriculture (with ICAR-IARI) & road construction (PMGSY).

- SAIL Green Tiles Plant at BSP produces 1,000 paver blocks/day using BOF slag.

Decarbonization & Renewable Energy

- Collaboration with SMS Group (Germany) & Primetals Technologies (Austria) for green steelmaking.

- Carbon Capture, Utilization & Sequestration (CCUS) pilot projects with Ram Charan Co. & IIT Mumbai.

- SAIL targets 12% CO₂ reduction by 2030 & net zero by 2070.

- 12.58 MW solar installed, expanding to 384 MW by 2028-29.

- Key solar & hydro projects:

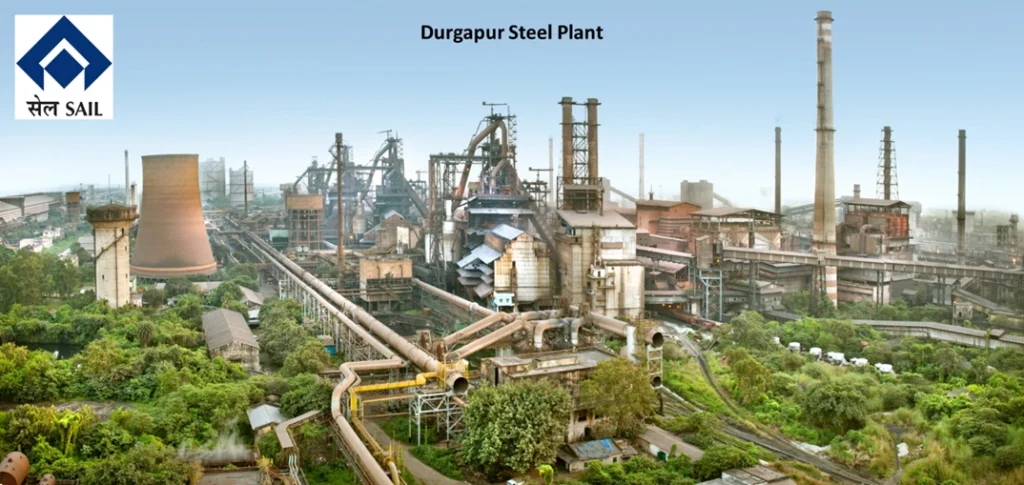

- 25 MW & 30 MW floating solar projects at BSL & DSP.

- 10 MW small hydro project at Mandira Dam (RSP).

Environmental Compliance & Risk Management

- Non-compliance at IISCO, VISP & Chandrapur Ferroalloy Plant → Show-cause notices issued by state pollution boards.

- Corrective actions implemented with time-bound improvement plans.

- No new Environmental Impact Assessments (EIA) required in FY 2023-24.

- Disaster Management Plan (DMP) in place, with regular safety drills.

Environmental Performance Improvements (FY 2023-24)

Through systematic environmental management and continuous upgrades to pollution control facilities, SAIL has achieved notable reductions in environmental impact over the past five years:

- Particulate Matter (PM) Emission Load reduced by 15% to 0.58 kg/tcs.

- Specific Water Consumption decreased by 14% to 3.02 m³/tcs.

- Specific Effluent Discharge reduced by 31% to 1.27 m³/tcs.

- Effluent Load dropped by 34% to 0.054 kg/tcs.

- 100% utilization of BF Slag (up by 1%).

- 113% utilization of BOF Slag (up by 102%, including stock usage).

- 102% total solid waste utilization (up by 16%).

Key Environmental Projects Completed (FY 2023-24)

SAIL has undertaken multiple infrastructure and technology upgrades to enhance environmental sustainability:

- Silica Reduction Plant at Dalli-Rajhara Mines.

- Effluent Treatment & Recycling Systems at DSP, RSP, ISP, and BSL.

- Cast House Slag Granulation Plants for improved waste management.

- Lagoon Management & Wastewater Recirculation Systems for reduced water consumption.

Adoption of Clean & Energy-Efficient Technologies

SAIL has integrated state-of-the-art clean technologies as part of its modernization and expansion plan, including:

- Coke Dry Cooling Plants & Computerized Combustion Control Systems to enhance energy efficiency.

- Top Pressure Recovery Turbines (TRT) & Coal Dust Injection (CDI) in Blast Furnaces for emissions reduction.

- Sinter Plant Waste Heat Recovery Systems to optimize energy use.

- Walking Beam Reheating Furnaces & Variable Frequency Drives in Rolling Mills for energy conservation.

- By-product gas-fired boilers for power generation.

Decarbonization & Carbon Capture Initiatives

SAIL is actively implementing strategies to reduce carbon emissions and transition towards carbon neutrality:

- MoU with SMS Group (Germany) & Primetals Technologies (Austria) for green steelmaking technologies.

- Pilot projects with Ram Charan Company & IIT Mumbai for Carbon Capture, Utilization & Sequestration (CCUS).

- Three-phase decarbonization plan to achieve 2.19 tCO₂/tcs by 2030-31 and eventually net zero emissions by 2070.

Waste Management & Circular Economy

SAIL follows a 4R approach (Reduce, Reuse, Recycle, Recover) to maximize resource utilization:

- Eco-friendly disposal of Polychlorinated Biphenyls (PCB) in collaboration with MoEFCC & UNIDO.

- BOF Slag utilization in agriculture through an R&D project with ICAR-IARI.

- Steel slag used in road construction under PMGSY.

- “SAIL Green Tiles Plant” established at BSP for paver block production from BOF slag.

Renewable Energy & Energy Efficiency

SAIL has commissioned 12.58 MW of solar power and is expanding its renewable energy capacity to 384 MW by 2028-29:

- Ongoing Solar & Hydro Projects in partnership with NSPCL & GEDCOL.

- Over 1 million LED lights installed, covering 84% of lighting needs.

- 7 MW bagasse-based renewable energy procurement.

Environmental Certification & Eco-Restoration

- ISO 14001-certified Environmental Management Systems (EMS) across plants & mines.

- Eco-restoration projects at Meghahatuburu & Kiriburu Iron Ore Mines with Institute of Forest Productivity, Ranchi.

- Extensive afforestation program with 2.5 lakh saplings planted in 2023-24.

To know more, visit –